Shanghai MK Aluminum Co., Ltd. is a T slot cover-T Slot Profile AccessoriesSuppliers and Company in China,Dongtai factory, occupying more than 210 hectares, includes 8 production buildings, 2 office buildings, and 1 apartment building, which is more than 200,000 square meters of building area in total. Since 2006 MK has specialized in aluminium extrusion design and production.

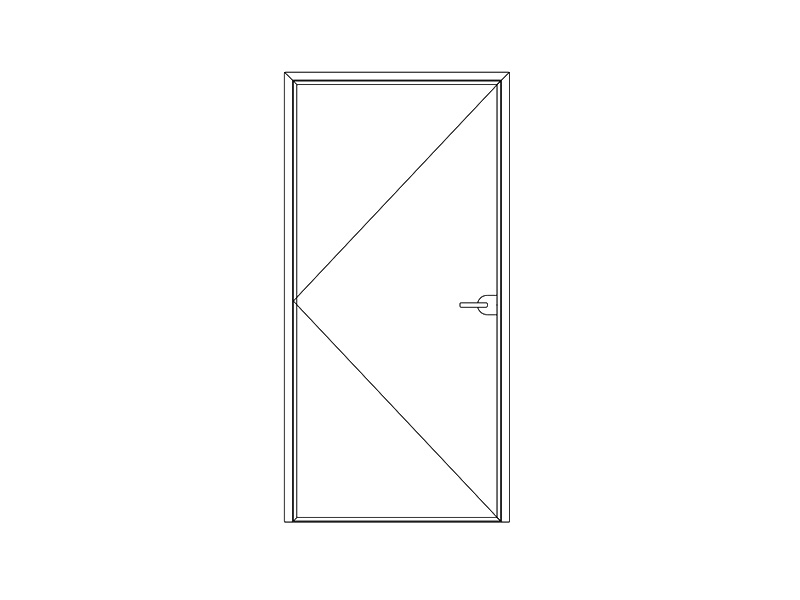

MK aluminum profiles are widely applied in modular assembly products, modular conveyors, machine frames, fences, workstations, linear motion products, stair and platform products, commercial complexes, resort hotels, apartment buildings, villa and office buildings, solar frames, solar racking products across the world. The annual output of aluminum profiles is over 60,000 tons.

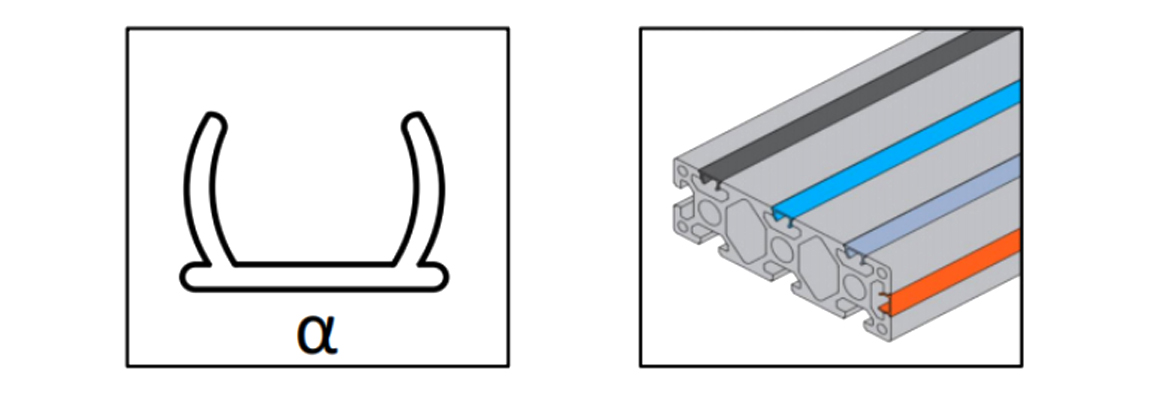

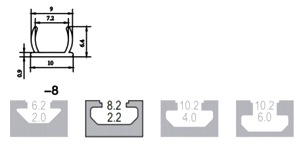

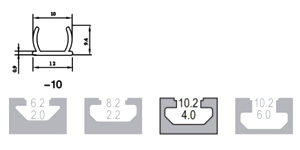

We have a professional R&D team with rich technical experience and innovation ability. The company focuses on technological innovation, constantly promotes the development of the field of intelligent equipment, and cooperates with customers to customize solutions that meet their needs. We can also Wholesale T slot cover-T Slot Profile Accessories in bulk.

With quality as the core, we strictly control the product manufacturing process to ensure product quality and reliability. The company's products comply with relevant international and domestic standards and have passed corresponding certifications and testing.