The Rise of Smart Aluminium Profiles

One of the most exciting trends in the development of aluminium building profiles is the integration of smart technology. With the advent of the Internet of Things (IoT) and smart building systems, aluminium profiles are being designed to support various smart technologies. For instance, aluminium windows and curtain walls can now be equipped with sensors that monitor temperature, humidity, and air quality. These sensors can connect to a building’s central system, allowing for real-time adjustments to the indoor climate.

This integration not only enhances the energy efficiency of buildings but also improves the comfort and well-being of occupants. For example, smart windows can adjust their opacity based on the intensity of sunlight, helping to regulate indoor temperature and reduce the need for air conditioning. Similarly, sensors embedded in aluminium facades can detect structural stress and provide early warnings of potential issues, improving building safety and reducing maintenance costs.

Aluminium Profiles for High-Performance Architecture

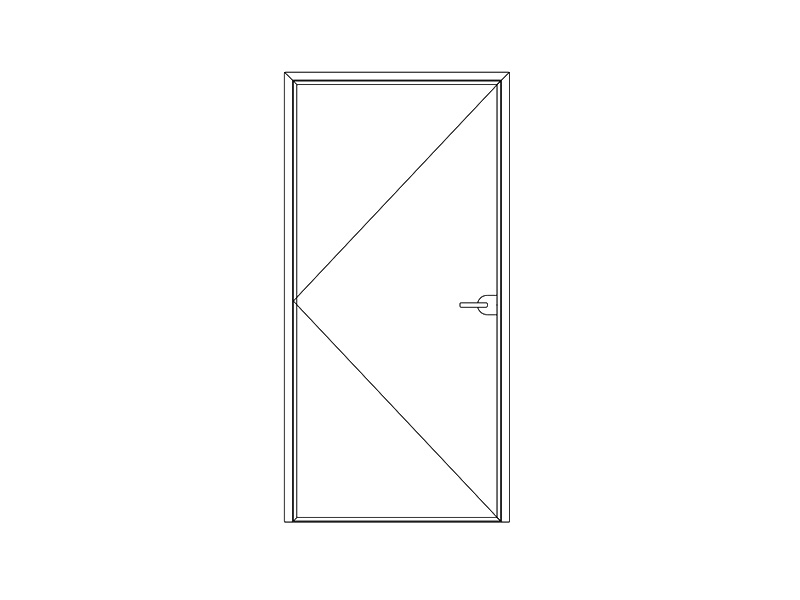

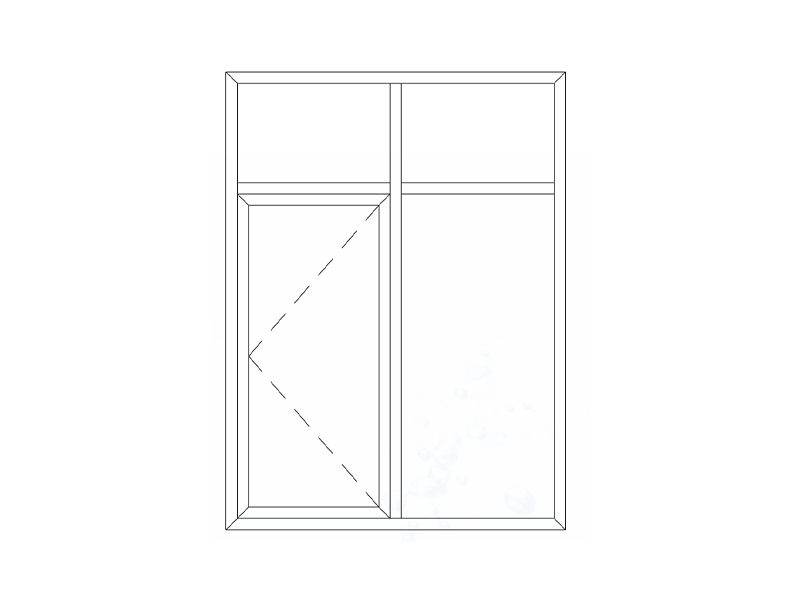

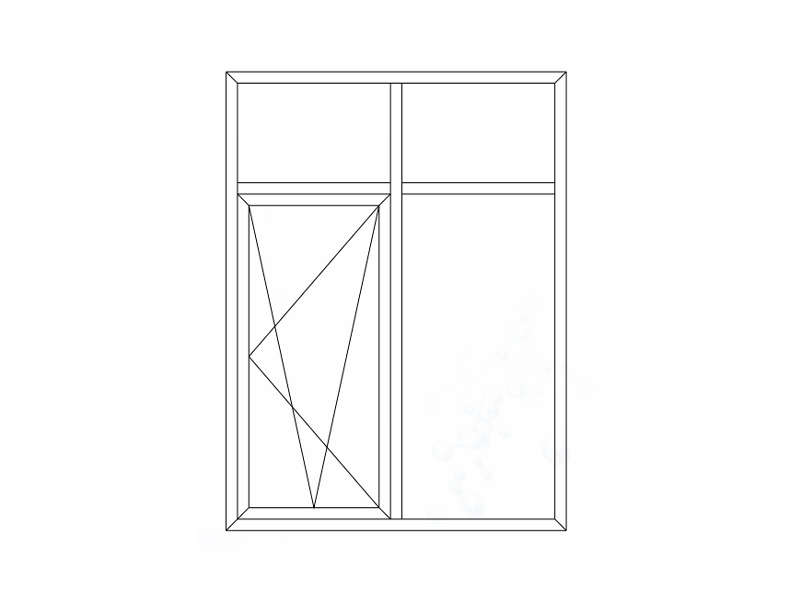

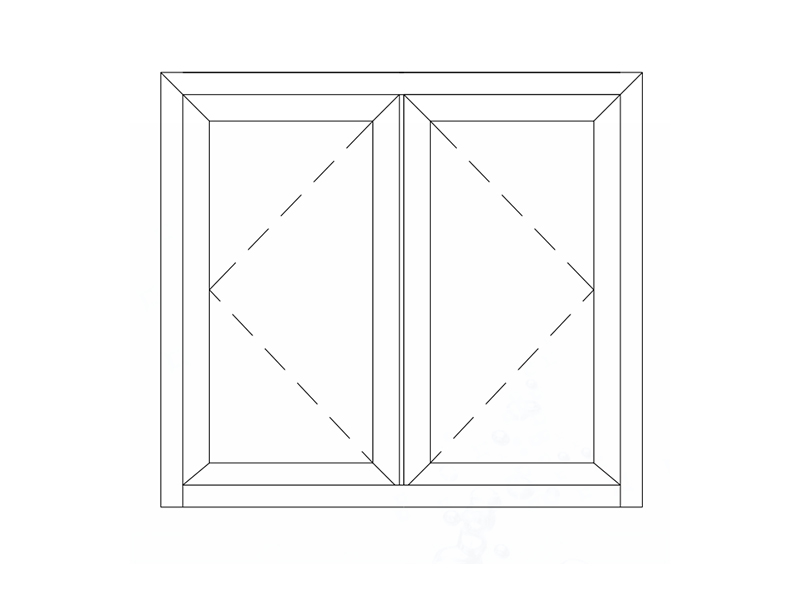

As buildings become more energy-conscious, the role of aluminium profiles in improving thermal performance is gaining prominence. High-performance aluminium profiles are now being developed with enhanced insulation properties. These profiles feature advanced thermal break technology, which reduces heat transfer and improves the overall energy efficiency of buildings. This is particularly important in regions with extreme weather conditions, where buildings need to be able to maintain a comfortable indoor environment year-round.

Thermal break aluminium profiles consist of a non-metallic section placed between the inner and outer metal parts of the profile, preventing thermal bridging and significantly improving thermal insulation. By reducing the amount of heat lost or gained through the building’s walls, windows, and doors, these profiles contribute to lower energy consumption and reduced heating and cooling costs.

The Importance of Sustainability in Aluminium Production

The demand for sustainable building materials is driving innovation in the production of aluminium profiles. Aluminium is already one of the most sustainable materials used in construction, as it is fully recyclable and can be reused multiple times without losing its properties. However, advancements in production techniques are making the process even more environmentally friendly.

One such advancement is the use of recycled aluminium in the manufacturing of building profiles. This reduces the need for virgin aluminium and minimizes the environmental impact of mining and refining. Additionally, energy-efficient manufacturing processes, such as the use of renewable energy in production plants, are helping to further reduce the carbon footprint of aluminium profiles.

Aluminium Profiles in Green Building Certifications

As green building certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) become more common, aluminium building profiles are increasingly seen as a key component in achieving these certifications. Aluminium’s energy efficiency, durability, and recyclability make it an ideal choice for projects seeking to meet sustainability standards.

In particular, aluminium’s ability to improve thermal insulation, reduce the need for energy-intensive materials, and contribute to the overall sustainability of a building makes it an attractive option for environmentally conscious developers. As green building initiatives continue to grow, aluminium will play an essential role in meeting the demands of the market and contributing to the global effort to reduce the environmental impact of construction.